Green Initiative

With a mission to go Green in all existing and new facilities, including the corporate head office at Dhaka, we have undertaken a determined plan for speedy execution. While ideas are evolving some of the key features of the inventiveness are here.

We are mindful in locating our facilities in zones that are not known to be fertile and arable. All sites selected are mostly devoid of trees and eroded lands. Cutting trees during construction phases were restricted and where it could not be avoided, were relocated. Carefully designed erosion and sedimentation control plans were executed at all construction sites to prevent the loss of topsoil as well as the pollution of air with dust and particulates. Our workforce generally resides in the neighborhood and most of them walk or ride bicycles to the plant. The management staff and those who live in the main city are transported to the sites using shared vehicles. These vehicles run on CNG rather than petrol. Special reserved parking is provided for pool vehicles. Substantial bicycle parking spaces together with changing rooms and shower facilities are also provided.

We are mindful in locating our facilities in zones that are not known to be fertile and arable. All sites selected are mostly devoid of trees and eroded lands. Cutting trees during construction phases were restricted and where it could not be avoided, were relocated. Carefully designed erosion and sedimentation control plans were executed at all construction sites to prevent the loss of topsoil as well as the pollution of air with dust and particulates. Our workforce generally resides in the neighborhood and most of them walk or ride bicycles to the plant. The management staff and those who live in the main city are transported to the sites using shared vehicles. These vehicles run on CNG rather than petrol. Special reserved parking is provided for pool vehicles. Substantial bicycle parking spaces together with changing rooms and shower facilities are also provided.

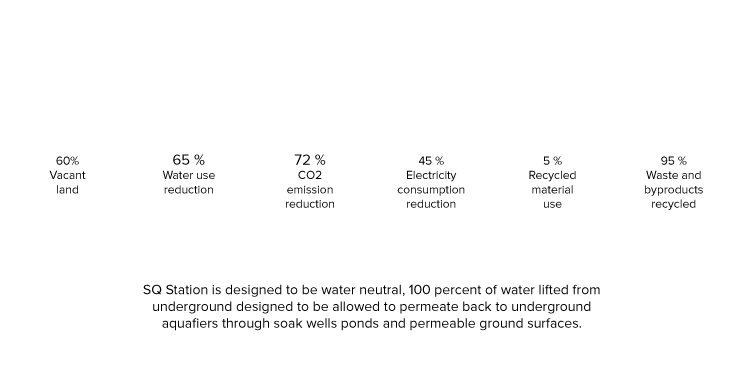

Water consumption at our sites is judiciously managed as demand for it is ever increasing particularly with the surge of population density. Buildings are built vertically to minimize the amount of ground used and thereby allow the rain and storm water to soak through and recharge the underground aquifers. Likewise, the hard paved road surfaces are kept to a minimum and replaced with permeable surfaces. Low water-usage toilet and plumbing fixtures are used and harvested rainwater is applied for flushing the toilets. The Station ultimately aims to be water neutral. All water withdrawn from the underground aquifer for human use as well as industrial processes is treated in the sewerage and ETP. It is then allowed to permeate back in the ground through the porous surface and specially built constructed wetlands.

Water consumption at our sites is judiciously managed as demand for it is ever increasing particularly with the surge of population density. Buildings are built vertically to minimize the amount of ground used and thereby allow the rain and storm water to soak through and recharge the underground aquifers. Likewise, the hard paved road surfaces are kept to a minimum and replaced with permeable surfaces. Low water-usage toilet and plumbing fixtures are used and harvested rainwater is applied for flushing the toilets. The Station ultimately aims to be water neutral. All water withdrawn from the underground aquifer for human use as well as industrial processes is treated in the sewerage and ETP. It is then allowed to permeate back in the ground through the porous surface and specially built constructed wetlands.

Facilities are sensibly designed for low energy consumption by reducing power demand and by using efficient equipment. As a design strategy, separate power transmission systems are employed for lighting, equipment and ventilation systems and these are carefully monitored through a building management system. All regular fluorescent bulbs are being decommissioned and replaced with energy efficient T5 tubes and needle point LED lamps. The older clutch and plate motor machines are being replaced with energy efficient direct drive and servo motor driven machines. These latest machines consume around five times less energy.

Facilities are sensibly designed for low energy consumption by reducing power demand and by using efficient equipment. As a design strategy, separate power transmission systems are employed for lighting, equipment and ventilation systems and these are carefully monitored through a building management system. All regular fluorescent bulbs are being decommissioned and replaced with energy efficient T5 tubes and needle point LED lamps. The older clutch and plate motor machines are being replaced with energy efficient direct drive and servo motor driven machines. These latest machines consume around five times less energy.

The peripheral lights of the buildings have been fitted with sensors to automatically monitor the general lighting levels. As the lux level rises above the 500 threshold, interior lights are selectively switched off in order to reduce energy consumption.

The building design aims to maximize the penetration of indirect daylight while restricting the direct sunlight that can cause overheating. To this end we have simulated the lighting conditions using software to optimize the fenestration designs. Louvers are used on the West face to restrict the direct afternoon sun. The North, South and East faces make use of window ledge to restrict direct sun penetration and light shelf to allow the reflected light to penetrate further into the interior space. By using passive building design to reduce heat loads and efficient evaporative cooling systems, rather than regular air conditioning, consumption of high amount of energy is avoided. We are also using renewable energy like solar power and exploiting the co-generation technology where excess heat from the generator exhaust and jacket cooling water is harvested through heat exchanger and used for air conditioning.

Energy expended to process and transport materials to the sites has been the primary selection criteria for sourcing of construction materials apart from price and quality. Majority of the construction materials are being sourced from within a 500 kilometer radius. Almost all steel used in the buildings, both in the form of rebar as well as for the steel structural elements, are recycled or reprocessed steel. Many of the other materials are also from recycled sources.

Energy expended to process and transport materials to the sites has been the primary selection criteria for sourcing of construction materials apart from price and quality. Majority of the construction materials are being sourced from within a 500 kilometer radius. Almost all steel used in the buildings, both in the form of rebar as well as for the steel structural elements, are recycled or reprocessed steel. Many of the other materials are also from recycled sources.

Efficiently designed ducted ventilation system and evaporative cooling system are used to keep indoor air always fresh. All interior finishes, such as, flooring system paints, coatings and wood products conform to the ASHRAE standards for low emitting. Windows are maximized and further use of skylights and light shelf as well as strategically located windows allow for greater indirect daylight penetration and uninterrupted views to 70% of the space.

Efficiently designed ducted ventilation system and evaporative cooling system are used to keep indoor air always fresh. All interior finishes, such as, flooring system paints, coatings and wood products conform to the ASHRAE standards for low emitting. Windows are maximized and further use of skylights and light shelf as well as strategically located windows allow for greater indirect daylight penetration and uninterrupted views to 70% of the space.

As an important element of Green initiative, we have recently started construction of a Green Bustle at SQ Station. The purpose of this Bustle is to establish a prototype facility that will be viewed as a role model and aspiring target for the Group. It is essentially an education, research and innovation bustle where we would educate our employees as well as visitors about sustainability principles. The Bustle will also be used as a testing ground for any new idea and technology that can later be put to practice in the rest of the manufacturing facilities.

As an important element of Green initiative, we have recently started construction of a Green Bustle at SQ Station. The purpose of this Bustle is to establish a prototype facility that will be viewed as a role model and aspiring target for the Group. It is essentially an education, research and innovation bustle where we would educate our employees as well as visitors about sustainability principles. The Bustle will also be used as a testing ground for any new idea and technology that can later be put to practice in the rest of the manufacturing facilities.

The entire facility will be powered by a set of solar panels. It will employ a prototype earth cooled ventilation system that takes advantage of the underground lower earth temperature to cool the air. The need for air-conditioning is met by making use of the cooling water from the central air conditioning units in other Station buildings and using it to cool the space further. The toilets will engage fixtures that minimize the use of water, like waterless urinals and low water use commodes. A prototype sewerage plant will process all wastes into fertilizer.

This project is being submitted for LEED certification and it is being designed to obtain the highest achievable score of 100 points under the Green rating system.

SQ Station is located in an area with green grass and other rich vegetation. Same can be said of the homes of most of our employees. There is a natural affinity to this type of a setting compared to a sterile factory type setting that exists now. With that in view and keeping in line with our Green mandate, a massive plantation program of trees, shrubs, and grass is currently underway. The uniquely selected plants and trees will significantly enhance the serenity and the overall eco-friendliness of the Station through their cooling properties and carbon seizure habits.

SQ Station is located in an area with green grass and other rich vegetation. Same can be said of the homes of most of our employees. There is a natural affinity to this type of a setting compared to a sterile factory type setting that exists now. With that in view and keeping in line with our Green mandate, a massive plantation program of trees, shrubs, and grass is currently underway. The uniquely selected plants and trees will significantly enhance the serenity and the overall eco-friendliness of the Station through their cooling properties and carbon seizure habits.

Extensive use of canopied trees will cover the hardscapes and road surfaces and will help reduce the heat island effect. Some buildings will also have grass roofs that provide insulation from the day heat, reduce the heat island effect of bare roof surface and will act as carbon sink. Trees are being collected from both home and abroad based on their sizes and utilities.

Few such trees will bear special fruits that can attract different type of birds. The result of the vegetation will also have an aesthetic impact to the area for which we have a long empathy. In few years, when these newly planted trees will spread out and flourish, SQ Station would be remarkable to behold.